Stock – Use Integrated Barcodes

Overview

Summary

- Use of barcode integration within stock control can significantly improve business processes.

- Your software can offer a number of additional features and benefits:

- Seamless Integration with stock control and transaction entry.

- Up to 20 characters per barcode.

- Allocate special price code to individual barcodes.

- Multiple barcodes per product.

- Can also be applied to services and assemblies.

- Barcode list report.

- Remote Data Capture.

A Rough Guide to Barcodes

A barcode can best be described as an “optical morse code.” Series of black bars and white spaces of varying widths are printed on labels to uniquely identify items. The bar code labels are read with a scanner, which measures reflected light and interprets the code into numbers and letters that are passed on to a computer. Because there are many ways to arrange these bars and spaces, numerous symbologies are possible. Common linear symbologies include UPC/EAN, Interleaved 2 of 5 (I of 5), Codabar, Code 39, and Code 128.

Figure 1: A typical bar code (Code 39)

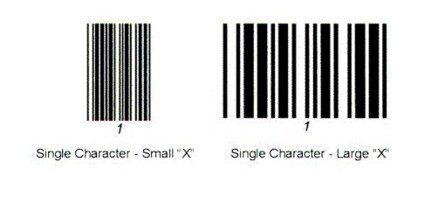

While each symbology is in some way unique, the composition of a complete message (bar code) is surprisingly similar regardless of the symbology used. For example, all bar codes are based on some “X” dimension. The “X” dimension is the narrowest bar or space in the bar code. Designated in “mils” (thousandths of an inch), symbology standards usually specify a minimum value “X” to insure compatibility between reading and printing equipment used in open systems.

The “X” dimension determines a bar code’s density. Density refers to the amount of information that can be captured in the bar code in a particular space, usually a linear inch. While not intuitively obvious, high density bar codes have low numbers (e.g., 5 mil) and low density bar codes have high numbers (e.g., 55 mil). This is because individual characters consist of some combination of bars and spaces that are each multiples of “X”.

When “X” is small, the area required for each character is less than when “X” is large; thus the bar code can hold more per linear inch and is said to be of higher density. Similarly, increasing the width of the narrowest element (“X”) increases the space required for each character and reduces the number of characters per inch. Because the resulting code is often quite large, very low density codes are often associated with applications such as warehousing that require reading bar codes from a significant distance (3 to 30 feet).

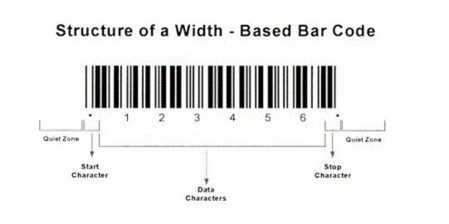

All bar codes have start/stop characters that allow the bar code to be read from both left to right and right to left. Unique characters placed at both the beginning and end of each bar code, the stop/start characters provide timing references, symbology identification, and direction of read information to the scanner. By convention, the unique character on the left of the bar code is considered the “start” and the character on the right of the bar code is considered the “stop.”

Immediately preceding the start character and following the stop character is an area of no markings called the quiet zone. Because there is no printing in this area, a scanning signal is not produced, thus the term “quiet.” The quiet zone helps the scanner find the leading edge of the bar code so reading can begin. As a rule, the quiet zone should be ten times the “X” dimension or 1/4″, whichever is greater.

Putting all these components together, we get a complete bar code such as the one found below. Notice the leading quiet zone followed by a start character, data, a stop character, and a final quiet zone.

Purpose:

A stock item can have a number of special prices. Use this to allow the same stock item to have a different barcode for each of the special prices.

Preparation:

Obtain an up to date list of Barcodes – see Stock Control – Barcode List form for how to produce a report of barcodes already in the system.

Refer to EPOS reader user manuals to ensure the correct conventions are used to produce new codes.

For further help and advice, contact your nearest Prelude Desktop supplier.

Processing:

On the main menu click Stock > Maintenance > Products to open the Product Maintenance form.

Or click the Create/Amend Products button from the toolbar – see Configure Toolbar.

Select an existing product or create a new one – see Create & Edit Products and Services.

Then click the Barcodes button to open the Barcode Maintenance form.

Update the barcode details as required and click OK to save your changes and close the form.

Barcodes can also be applied to services. Create document with Description of Service and corresponding Barcode.

0 Comments