SCM – Forecast Stock Based On Current Levels And Orders

SCM – Overview

The software is designed with Supply Chain Management as one of its major features.

Integrated with the Stock Control, Sales and Purchase Order Processing modules, it offers the ability to maintain and forecast stock levels taking into account current levels and future Sales and Purchase Orders.

A user-defined calendar helps you to plan Purchase Orders in advance.

Purchase orders can be produced automatically to maintain re-order levels, minimum stock levels or simply to maintain a positive stock level, thereby minimising the risk of shortfalls and excess stock levels.

The features of Supply Chain Management include:

- User-defined stock level projection calendar.

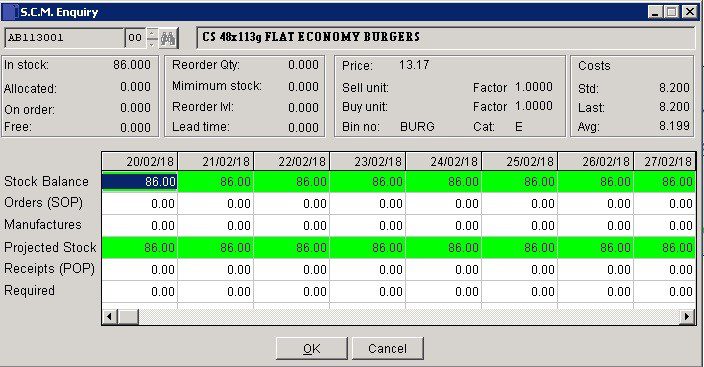

- Colour-coded enquiry screen with drill-down to underlying detail.

- Maintain stock levels at re-order level, minimum stock or just positive stock.

- Include stock assemblies.

- Automatically create Purchase Orders.

Forecast Stock

Purpose:

To check stock movements in and out to ensure stock is always available. This is also the basis for planning deliveries from stock.

Processing:

SCM will be a series of enquiries in order to take appropriate action.

From the main menu – S.C.M > S.C.M Enquiry to locate and open form.

Forecast Stock Based on Current Levels and Orders

Select the product for which you want to project stock levels.

Stock Balance: The quantity in stock at the beginning of the particular projection period:

For the first period, this will usually be the current stock level.

For subsequent periods, this will be the result of the level plus the movements in the prior period.

0 Comments